Kayaba (KYB) Genuine Parts Rear Shock Bump Rubber KYB 12.5mm x 34 x 40

OEM KYB Japan Motorcycle Suspension Service Parts(SKU: 120341200101)

14 In Stock

Find your Bike:

Your motorbike's coilover needs an assembly to attach the coil spring to the main shock absorber shaft bottom end - shaping these parts as a holder cup means it holds the bottoming stop safely in place too.

If your rear suspension bottoms out (fully compressed), the last line of defence before that force creates expensive damage are these elastomer bumpers. When your compression damping is exhausted, they help protect against a cracked sump, bent chassis & shattered shocks internals. Bump stops come in a huge range of shapes & sizes, but are all designed to act like a progressive rate spring absorbing force, softening the blow with gentle initial contact but rising to rock hard resistance over the last bit of travel.

They need regular replacing as rubber components harden over time, eventually cracking & crumbling away.

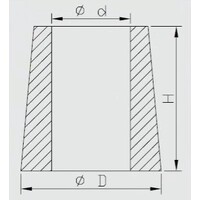

| d | Bumper shaft inside diameter |

| D | Bumper outside diameter al largest section |

| H | Overall Height |

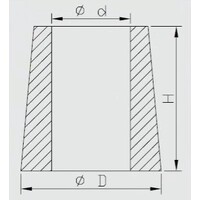

| d | Bumper shaft inside diameter |

| D | Bumper outside diameter al largest section |

| H | Overall Height |

Your motorbike's coilover needs an assembly to attach the coil spring to the main shock absorber shaft bottom end - shaping these parts as a holder cup means it holds the bottoming stop safely in place too.

If your rear suspension bottoms out (fully compressed), the last line of defence before that force creates expensive damage are these elastomer bumpers. When your compression damping is exhausted, they help protect against a cracked sump, bent chassis & shattered shocks internals. Bump stops come in a huge range of shapes & sizes, but are all designed to act like a progressive rate spring absorbing force, softening the blow with gentle initial contact but rising to rock hard resistance over the last bit of travel.

They need regular replacing as rubber components harden over time, eventually cracking & crumbling away.

After you've replaced your hardened, damaged, broken or disintegrated stopper, it gets held by the conical guide attached to the base of the damper rod. A lock ring (shaped like a big c-clip) is sat on top to keep the spring concentric around the shock body. This locking retainer collar is slid in while replacing shock springs. Many shocks then include a perch or seat to distribute pressure evenly, which can also act as a spacer washer to adjust pre load - learn more about spring rate, preload & sag. Some shim spacers can go at either end - see our shock spring hardware.

If your rider weight is beyond what the factory expected, you're racing & landing big jumps, or have a lowering link installed for a lowered seat height - if your bike's shock body base is consistently hitting your bump stop you are doing damage to your damper - tune your comp damping to maximum. If it's already maxed out it might be time for a shock revalve - try our damping piston valving kits. You're not just prolonging your motorcycle's life by stopping smashing jolts and limiting thumps; you're maximizing it's performance with the extra shock absorption - more support & cushioning mean you can be more comfortable, ride faster & longer.

© 2025 Teknik Motorsport Pty Ltd. ABN: 29137380324. All rights reserved.